No products in the cart.

The International Institute of Gemology (IIG) recently conducted a two-day industrial visit to Surat for its diamond and jewellery students, an initiative carefully designed to take learning beyond textbooks and into the rhythm of real industry.

IIG has long maintained that professional confidence is not built by theory alone. It is shaped by exposure, by observing how decisions are made on production floors, how systems are structured, how time is valued, and how accountability travels from one department to another.

This visit to Surat was conceptualized with that clarity.

Surat processes the vast majority of the world’s diamonds. To understand the diamond trade without witnessing Surat in action is to understand it only partially. The visit was therefore structured as a guided immersion into the full value chain, so students could connect what they study with how the industry actually breathes.

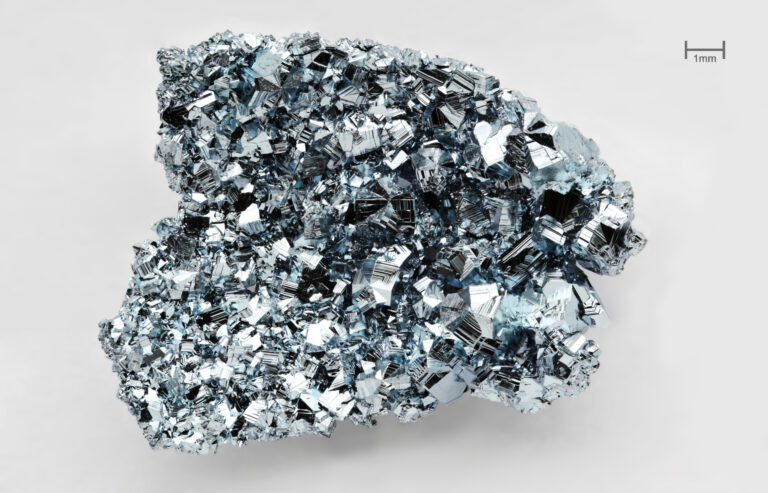

At Hari Krishna Exports, students followed the journey of a diamond from rough sourcing to planning, cutting, bruting, polishing, grading, and final certification. They observed how microscopic decisions at the planning stage determine value outcomes downstream. A guided hands-on polishing experience taught the precision and steadiness required to transform potential into brilliance.

The students also had a brief interaction with Mr. Brijesh Bhai Dholakia who shared insights with our aspiring diamond professionals.

At Lexus SoftMac, the conversation shifted toward technology. Students were warmly welcomed by Mr. Janak Bhai Mistry welcomed us warmly who shared visionary insights into how artificial intelligence and advanced technologies are transforming the diamond and jewellery industry.

The group got a firsthand look at how AI is being woven into the DNA of modern manufacturing. They watched as high-tech systems analyzed natural color diamonds and rare gems—tools that don’t just speed things up, but actually strip away the guesswork and sharpen precision.

It served as a clear signal: to thrive in diamonds today, you have to be as handy with a data set as you are with a loupe. The future of the trade will belong to those who understand both.

At HK Jewels, students were hosted by Praveen Bhai Tiwari, whose leadership keeps their extensive manufacturing wing on track. The tour covered the entire production lifecycle, including CAD, casting, and dispatch. By seeing these processes in action, the students learned that tight system management isn’t about cutting out the human element; it’s about creating a framework where human skill can be more effective and reliable. For students who aspire to build enterprises of their own, that lesson may prove more valuable than any single technical skill.

The trip wrapped up at Jaykar Diamond, where Kavith Bhai Parikh showed the group how to break into the industry without owning a single machine. He walked them through how a new entrepreneur can ethically source production space, turn rough stones into polished ones, and stay accountable every step of the way. For many students, this was an eye-opener—it proved that you don’t need a massive factory to start making your mark in the diamond world.

Mr. Rahul Desai, CEO and Managing Director of IIG, has consistently advocated that education in the gem and jewellery sector must prepare students not only to pass examinations, but to steer through industry realities. Reflecting on the visit, he stated, “When students see how leadership thinks, how production moves, how technology is applied, they begin to understand the industry as a system. That awareness cannot be simulated in a classroom. It must be experienced.”

The Surat visit forms part of a larger academic philosophy at IIG, one that integrates destination-based industry exposure into its training approach. Each visit is curated with intent: to help students observe leadership behavior, operational discipline, technological integration, and market alignment firsthand. These are the intangible dimensions of professional readiness, i.e the judgment, composure, and systems awareness that distinguish a graduate from a practitioner.

Students returned not only with technical reinforcement, but with sharper questions and clearer aspirations. They witnessed how diamonds move across departments with traceability and how large teams function within defined hierarchies.

In industries built on precision, small miscalculations carry large consequences. Exposure to such environments early in one’s training creates maturity. As one student reflected on the return journey, “We had studied every stage. But seeing it happen in real time changes how seriously you take each step.”

The International Institute of Gemology remains committed to creating professionals who are technically sound, commercially aware, and grounded in industry realities. Surat was not an excursion. It was a deliberate investment in perspective. In the end, education must do more than inform. The goal is to give every student the poise and expertise to hold their own in any corner of the trade. By organizing these deep dives into the industry, IIG bridges the gap between the classroom and the real world, making sure its graduates hit the ground running.

Not a member yet? Register now

Are you a member? Login now